The DIAMOND-SIS® has over 2 million online hours without a dangerous failure rate or spurious incident.

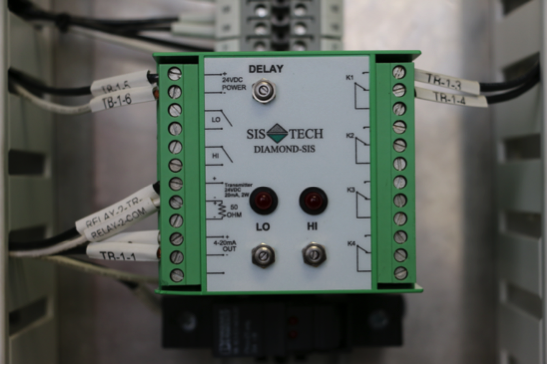

DIAMOND-SIS®

The DIAMOND-SIS® Solution:

- Independent alarm/trip system with over 2 million operational hours and zero failures

- Certified to IEC 61508 SIL 3.

- FM Approved Class I Division 2.

- Cyberproof via air gapped and non-programmable countermeasures.

- Independent of process control system.

- Simple construction and easy maintenance.

- Low capital and installed cost.

- Local panel with status indication/alarm, manual reset, and manual shutdown.

- Local panel reduces capital and installation costs by 90% compared to safety PLCs.

- Supports 24VDC, 110VAC, or 240VAC.

- Optional redundant power supplies, UPS or solar power.

- Control room communication options include hardwired, serial, or wireless.

- Health status with local indication and capability to repeat signals back to DCS.

- Complete IEC 61511 design package with proof test procedures.

- Annual service packages for long-term SIS maintenance support.

Advantages of DIAMOND-SIS® in AOPS Applications:

- Compliance with API 2350 and IEC 61511.

- Certified to IEC 61508 SIL 3.

- FM Approved Class I Division 2.

- Independent of automated tank gauging (ATG) system.

- Simple construction and easy maintenance.

- Low capital and installed cost.

- Local panel with status indication/alarm, manual reset, and manual shutdown.

- Locally installed automated overfill protection system (AOPS).

- Cyberproof AOPS via air gapped and non-programmable countermeasures.

- Complete IEC 61511 design package with proof test procedures.

- Annual service packages for long-term AOPS maintenance support.

Advantages of DIAMOND-SIS® in BMS Applications:

- Compliance with API 556, NFPA 85, NFPA 86, NFPA 87, and IEC 61511.

- Certified to IEC 61508 SIL 3.

- FM Approved Class I Division 2.

- Independent of burner control system.

- Simple construction and easy maintenance.

- Low capital and installed cost.

- Local panel with status indication/alarm, manual reset, and manual shutdown.

- Locally installed burner management system (BMS).

- Supports local purge and light-off sequence.

- May be specified to execute any BMS function, such as purge, light off, fuel pressure, flame detection, pass flow, drum level, fire box pressure, and knock-out drum level.

- Cyberproof BMS via air gapped and non-programmable countermeasures.

- Complete IEC 61511 design package with proof test procedures.

- Annual service packages for long-term BMS maintenance support.

Coker Drum De-Heading Solution:

- Safe unheading of Coke drums.

- Certified to IEC 61508 SIL 3.

- IEC 61511 compliant and proven in Coker applications.

- FM Approved Class I Division 2.

- Independent of coke drum sequencing.

- Simple construction and easy maintenance.

- Low capital and installed cost.

- Local panel with status indication/alarm, manual reset, and manual shutdown.

- Locally installed coke drum protection relies on overhead pressure, overhead temperature and inlet temperature.

- Cyberproof SIS via air gapped and non-programmable countermeasures.

- Complete IEC 61511 design package with proof test procedures.

- Annual service packages for long-term SIS maintenance support.

HIPS Solution:

- Pipeline and vessel high integrity protection system (HIPS).

- Certified to IEC 61508 SIL 3.

- Compliant with API 521 and UG-140 of ASME Section VIII, Division 1 and 2.

- IEC 61511 compliant and proven in HIPS applications.

- Exceeds the performance of traditional relief valves.

- Dedicated to each high pressure hazard same as traditional relief valve.

- FM Approved Class I Division 2.

- Independent of process control system.

- Simple construction and easy maintenance.

- On-line diagnostic and repair capability.

- Low capital and installed cost.

- Local panel with status indication/alarm, manual reset, and manual shutdown.

- Cyberproof HIPS via air gapped and non-programmable countermeasures.

- Complete IEC 61511 design package with proof test procedures.

- Annual service packages for long-term HIPS maintenance support.

Advantages of DIAMOND-SIS® in AIB Applications:

- Automated independent backup for DCS interlocks.

- Certified to IEC 61508 SIL 3.

- Provides low cost separation of process control and SIS.

- Upgrades legacy DCS to IEC 61511 compliance.

- FM Approved Class I Division 2.

- Simple construction and easy maintenance.

- Low capital and installed cost.

- Cyberproof SIS via air gapped and non-programmable countermeasures.

- Complete IEC 61511 design package with proof test procedures.

- Annual service packages for long-term SIS maintenance support.