Reduces Time Required to Execute Turnaround Testing

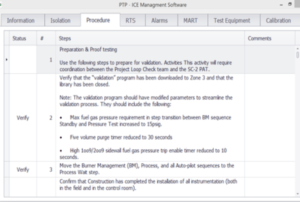

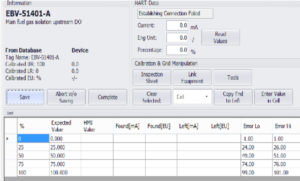

The ICE-Manager reduces the time required to execute turnaround testing of safety and asset protection by integrating documentation, procedures and forms in a single platform for efficient field deployment. The ICE-Manager eliminates the need to create physical files to support inspection, calibration and testing. The field technician is issued a smart tablet with everything needed, such as specifications, procedures, installation diagrams, manufacturer manuals, and forms. With HART connectivity, the ICE-Manager captures instrument data automatically without manual entry.

“The ICE-Manager like many of our other products was initially developed to increase the efficiency of our work execution,” reports Angela Summers, President of SIS-TECH. “In this case,” she continues, “we wanted to eliminate the hard copy paperwork that is commonly used for maintenance records. The advantages of the seamless integration of the technical specifications, maintenance data sheets, and data quality assurance were clearly demonstrated to our field personnel from the first beta test through full-scale turnaround implementation.”

“The ICE-Manager like many of our other products was initially developed to increase the efficiency of our work execution,” reports Angela Summers, President of SIS-TECH. “In this case,” she continues, “we wanted to eliminate the hard copy paperwork that is commonly used for maintenance records. The advantages of the seamless integration of the technical specifications, maintenance data sheets, and data quality assurance were clearly demonstrated to our field personnel from the first beta test through full-scale turnaround implementation.”

Safety-critical and protective instrumentation must be periodically inspected and tested. Most companies create physical files containing procedures, forms, and specifications for the field technician to use to conduct and document the field work. This paper-driven process provides little data governance and no ability to rapidly deploy updated documents.

The ICE-Manager is designed to manage work flow, eliminate paper, and ensure quality record retention. Using a mobile maintenance interface maximizes turnaround value by getting data that drives reliability improvement into the hands of the people who can act on it.

The ICE-Manager is designed to manage work flow, eliminate paper, and ensure quality record retention. Using a mobile maintenance interface maximizes turnaround value by getting data that drives reliability improvement into the hands of the people who can act on it.

Smart tablets are constructed of rugged hardware suitable for hazardous environments and the user interface is ergonomically configured for use in the field. Their innovative design, slim profile, and HART compatibility allows the ICE-Manager to leverage the latest mobile interfaces to support in-service testing of any instrumented safeguard, including safety controls, safety alarms, interlocks, and safety instrumented systems.

Smart tablets are constructed of rugged hardware suitable for hazardous environments and the user interface is ergonomically configured for use in the field. Their innovative design, slim profile, and HART compatibility allows the ICE-Manager to leverage the latest mobile interfaces to support in-service testing of any instrumented safeguard, including safety controls, safety alarms, interlocks, and safety instrumented systems.

The ICE-Manager boosts efficiency by providing the information that instrumentation and controls needs in the field and by electronically capturing maintenance data to support analytics and quality assurance. The durable and light weight tablet eliminates double entry of maintenance data and bulky test equipment.

The ICE-Manager boosts efficiency by providing the information that instrumentation and controls needs in the field and by electronically capturing maintenance data to support analytics and quality assurance. The durable and light weight tablet eliminates double entry of maintenance data and bulky test equipment.

Advantages of the ICE-Manager:

- Electronic delivery of proof test procedures, calibration sheets, and other maintenance forms

- Electronic records for calibration, inspection, and proof test

- Enhances collaboration between technicians and execution coordinators

- Track task execution with each sync

- Helps eliminate information silos and time gaps

- Reduces the cost of field data capture

- Provides visibility of recurrent problems

The ICE-Manager reduces maintenance time, eliminates hard copy paperwork, increases maintenance record quality and improves your ability to analyze and improve instrumentation and controls performance.