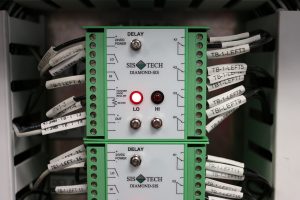

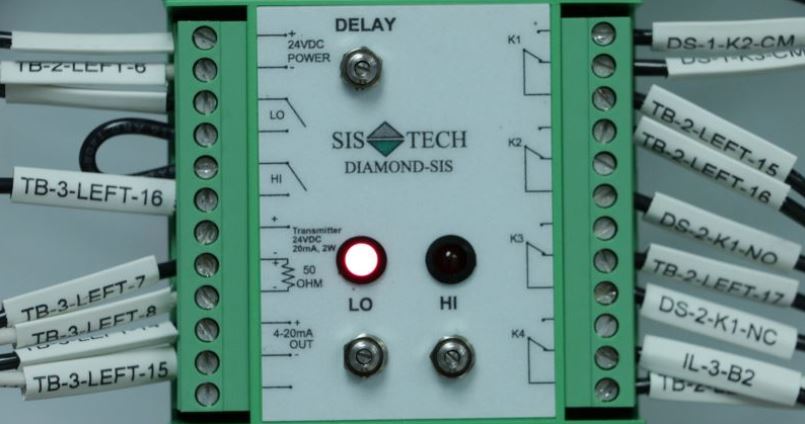

SIS-TECH announces its new Tank Protection System (TPS) – an independent, cyber-proof system that uses the Diamond-SIS® to monitor and report asset threatening conditions in terminals, tank farms and process vessels. The Diamond-SIS® is a state-based controller rated for hazardous locations, allowing local installation, minimizing installation and wiring costs. The Diamond-SIS® is specifically designed for low I/O applications and its installed cost is 10% of conventional safety controllers. The Diamond-SIS® has over a decade of continuous industrial service with zero reported failures and is certified for use in SIL 3 applications.

The TPS is flexible and customizable for any application. A popular configuration provides dual alarms for each condition of concern, a local operator interface for safe operation and shutdown, and an automatic overfill prevention system (AOPS). The low power consumption of the Diamond-SIS® is ideally suited for solar power where utilities don’t exist. Options are available for communicating tank fill status to remote monitoring stations.